Introduction

BladeFlo® self-cleaning filter, automatically removes particles from the filter element surface by the efficiently mechanical scraping, can work on-line continuously, consumes no disposal filter media, requires no frequent manual cleaning, is capable of the filtration for both normal and high viscous liquids. BladeFlo® self-cleaning filter, the motor drives the scraper to rotate and remove the particles on the filter element internal surface. BladeFlo® self-cleaning filter are good for the high viscous liquid.

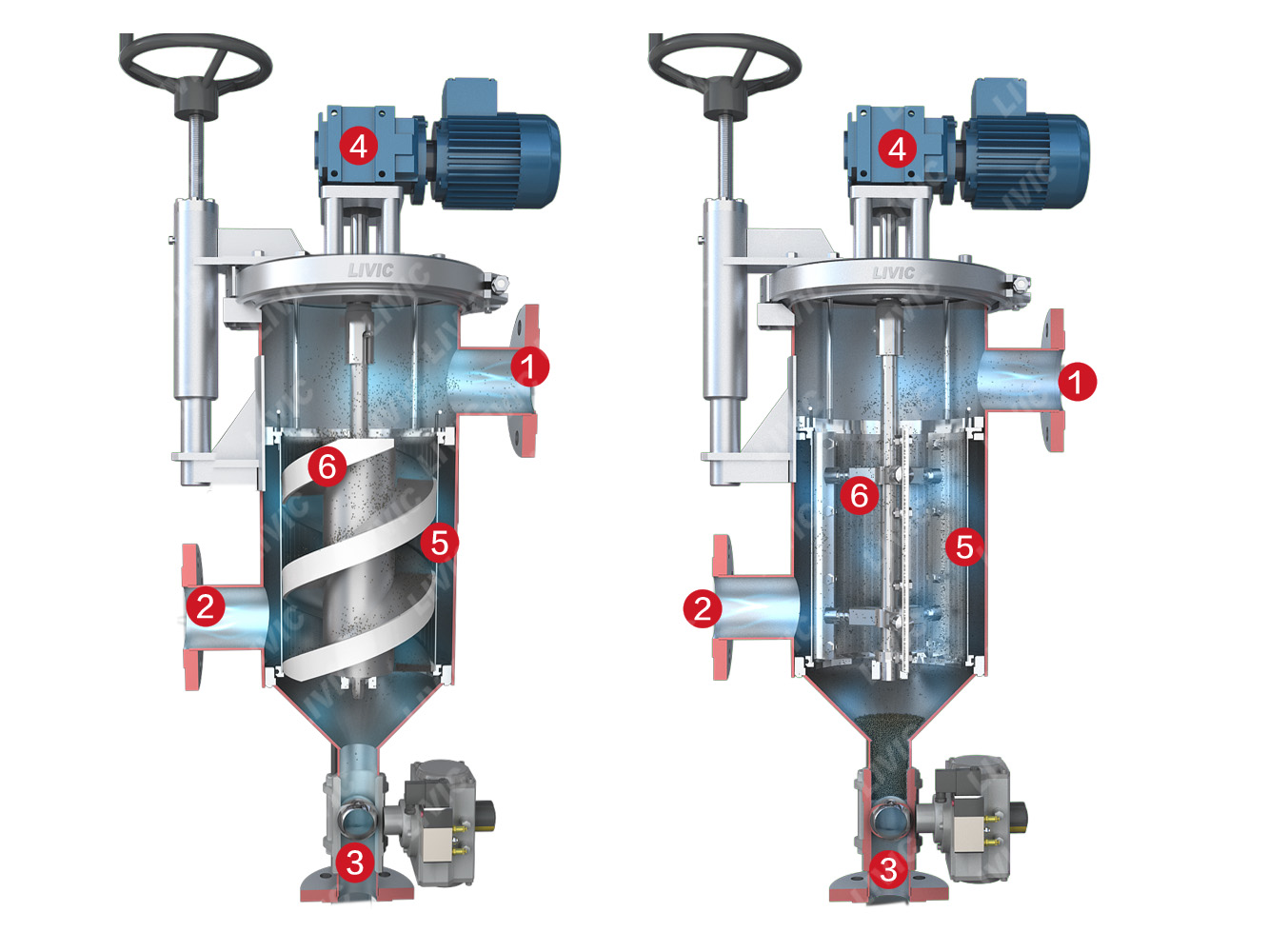

Working Principle

The liquid enters the filter from the inlet(1), flows through the filter element(5) from inside to outside. The filter element bottom is connected to the outlet(2), through which the liquid flows out. After the filter element captures the impurities, the cleaning action is triggered by the preset time or differential pressure value. The gear motor(4) drives the scraping blades(6) to rotate and remove the impurities on the inner filter element surface. The impurities moves off along the blades and falls down to the filter bottom. The impurities are collected at the filter bottom. The discharging valve opens per the preset time and purges the waste liquid with high impurity concentration through the drain outlet(3), the waste liquid can be reclaimed if necessary.

Specification

| Sub-series | M20 M41 M71 |

|---|---|

| Filter Area(c㎡) | 2070 4140 7140 |

| Volume(L) | 35 53 175 |

| Applicapable Liquid | water and viscous liquids(<800,000cps), impurity<1000ppm |

| Filtration Degree | 50-3000μm |

| Standard Design Pressure | 1.0mPa, high design pressure available |

| Design Temperature | 0-200℃( depend on the seal material) |

| Clean Differential Pressure | 0.05mPa |

| Differential Pressure Instrument | Differential pressure tansmitter(DPT)/ Differential Pressure Switch(DPS) |

| Gear Motor | 180W, three phase, 380V, protection class IP55, worm reduction gear motor |

| Inlet and Outlet Standard | Flange, HG20592-2009(standard), HG20615-2009(ANSI B16.5 Compatible) |

| Filter Element Type | V-SLOT slotted metal filter element, 316L material |

| Housing Wet Part Material | 304/316L/CS |

| Scraping Blade Material | 304/316L |

| Housing Seal Material | NBR/VITON(FKM) |

| Discharging Valve | Pneumatic ball valve, protection class IP65 |

| Supply Facility Requirement | 380V AC, 0.4-0.6mPa clean and dry compressed air |

Filters on Jobsites

Applicable Liquid Types: wax, coal oil, monomer, polymer, citric acid, fermented broth, cosmetics, silicon solution, soap, sorbitol, steriodsugar, wet end additives, adhesives, inks, lubricating oils, coatings, resin, rubber, ethanol, miscella, edible oil, juice, diesel, etc.

|

1. Coatings Filtration |

2. Miscella Filtration |

|---|

| 3.Fermatation Broth Filtration | 4. Water Treatment Filtration |

|---|