MF Series Modular Self-cleaning Filter

Introduction

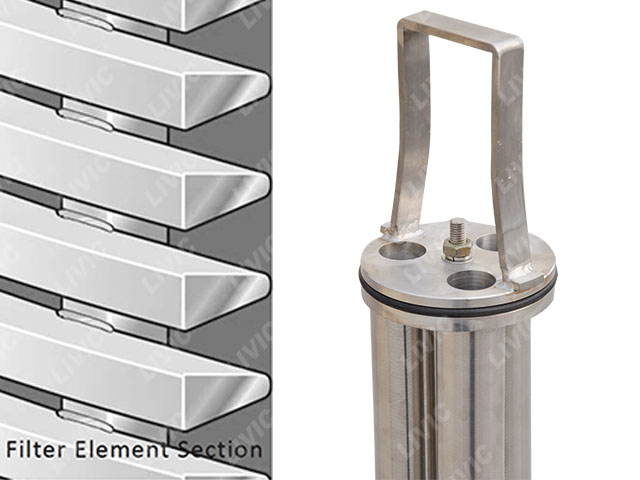

MF Series Modular Self-cleaning Filter , designed on the base of modular concept, MF filter consists of several standard filter units and has high safety redundancy. And the operator can flexibly add online filter units to the exsiting system for higher flowrate or dirty load capacity. MF filter works automatically and is easy for capacity expansion. It can works in low pressure condition by flushing with external high-pressure back-flushing fluid. It adopts the unique V-SLOT filter element, which can be back-flushed clean thoroughly and costs less of back-flushing liquid. When filtering some viscous impurities or fibers, it is easy to open for periodic manual cleaning. MF filter not only can purify fluid, protect key equipment, but also can reclaim expensive solid particles from the back-flushed liquid. MF filter adapts to low viscosity liquids, such as raw water, sewage, gasoline, heavy gasoline, diesel oil, residual oil.

Specification

| Sub-series | MFR MFV |

|---|---|

| Back-flushing Fluid | clean Filtrated Liquid external liquid or gas |

| Applicable Liquid | <50cps <100cps |

| Contaminant Contnt | <300ppm |

| Inlet Pressure Requirement | >0.3MPa <0.3MPa |

| Installation Position | Behind the pump Before the pump |

| Filtration Degree | 50-500μm 20-500μm |

| Standard Design Pressure | 1.6mPa, 2.5mPa, 4.0mPa |

| Design Temperature | 0-250℃(depend on the seal material) |

| Filter Module Quantity Per Single System | 3-24 |

| Inlet&Outlet Valve Size of Filter Module | DN50, max flowrate 25m³/h, DN65, max flowrate42m³/h |

| Inlet&Outlet Connection Standard | Flange, HG20592-2009(DIN compatible), HG20615-2009(ANSI B16.5 compatible) |

| Filter Element Type | V-SLOT slotted metal filter element(200-2000μm);POR perforated filter element(1000-2000μm) |

| Filter Element Material | 316L/Duplex Stainless Steel |

| Pistion Material | 316L |

| Housing Wet Part Material | 304/316L/CS/GRP |

| Anticorrosion | Nelon11 |

| Housing Sealing Material | NBR(Standard)/VITON(FKM) |

| Discharging Valve | Pneumatic Butterfly Valve, Protection gradeIP65 |

| Facility Supply Requirement | 0.6MPa clean and compressed air, 110V/220V(Standard)/380V/440V AC,24V DC |

Filters on Jobsites

Applicable liquid types: raw water, process water, clean white water, super clean water, circulating cooling water, high pressure spraying water, low pressure spraying water, sealing water, squirt cut water, etc.. Various raw oils like diesel, gasoline, naphtha, residual oil; hot rolling coolant or cold rolling coolant in the steel mill

|

1. Clean White Water Filtration |

2. Super Clean Water Filtration |

|---|

| 3.High Pressure Spraying Water Filtration | 4. Fresh Water Filtration |

|---|

Additional Information

■ V-shape slot, hardly be clogged, keep stable flowrate

■ Good at filtering impurites like micro fibers, oil-mud and soft particles

■ Solid structure, no slot deformation when the D.P increases

■ High resistance against the forward and reverse pressure

■ Filtrartion degree ranges from 20 μm to 500 μm

■ Accurate surface slot, accurate filtration

■ Made of 304 or 316L, good chemical resistance

■ Smooth outside surface, easy to clean manually