DFA Series Scraping Self-cleaning Filter

Introduction

DFA series pneumatic scraping self-cleaning filter (DFA FILTER for short), is the new high performance scraping self-cleaning filter independently developed by LIVIC. It automatically removes the particles and impurities from the filter element internal surface by mechanical scraping and it can continuously work on-line. DFA series scraping self-cleaning filter is designed for filtration of high viscosity up to 800000mPa.s. The filtration degree ranges for 50-1500μm. It can scrape the impurities off the filter element surface most quickly, which makes it more efficiently removing the impurities. It is applicable for water and various viscous liquid. DFA series scraping self-cleaning filter is designed and manufactured by following LIVIC´s high performance, high quality and high reliability standard.It is a world-class quality filter. We are proud that we offer DFA series scraping self-cleaning filters with the highest reliability, advanced filter elements and the comprehensive models. We are the world-leading manufacturer of this kind of filter and we offer customers the proven automatic filtration technology for viscous liquid.

Working Principle

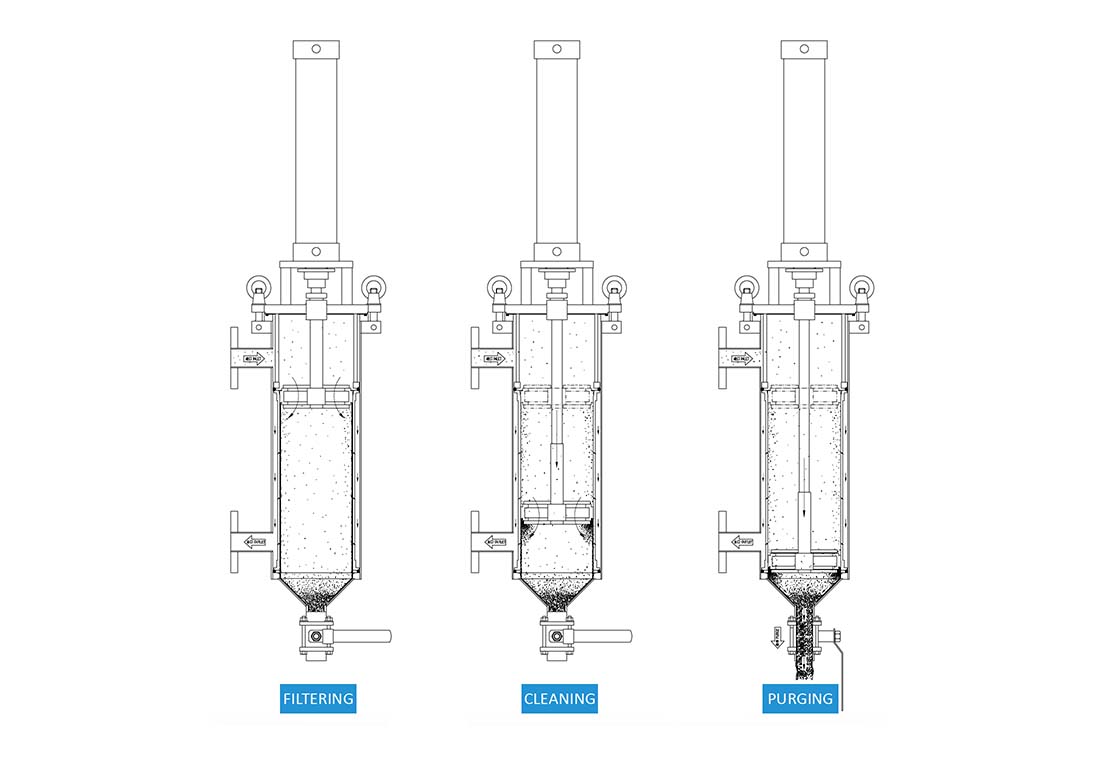

[Filtering Status]Liquid enters the filter, passes the scraper and flows across the filter element from inside to outside. The impurities are blocked on the inner element surface. The liquid flows out from the outlet. After running for a period, more and more impurities accumulate and the pressure drop increases.

[Cleaning Status]The scraper moving down, the impurities are pushed down to the bottom. The scraper moving up, the remaining impurities are pushed to the top of the filter element and then flushed off by the liquid. The scraper moving down, the impurities is scraped off again. When cleaning, the filter works on-line continously.

[Purging Status]After several cleaning cycles, the impurities accumulate more and more. Open the valve periodically and purge the waste liquid of high impurity concentration, which can be recovered if necessary.

Click to Watch Working Principle ![]()

Specification

| Sub-Seires | DFA7 DFA22 DFA41 DFA71 DFA213 DFA284 |

|---|---|

| Filter Area(㎡) | 0.07 0.22 0.41 0.71 2.13 2.84 |

| Filter Element Qty. | 1 1 1 1 3 4 |

| Volume(L) | ~4 ~24 ~42 ~175 ~620 ~760 |

| Inlet&Outlet Size | DN25-DN50 DN50-DN80 DN65-DN100 DN80-DN125 DN100-DN150 DN150-DN250 |

| Purge Size | DN40 |

| Applicable Liquid | water and viscosity liquid(<800,000mPa.s), impurities content<1000ppm |

| Filtration Degree | 50-2000μm |

| Standard Design Pressure | 1.0MPa, higher design pressure available |

| Design Temperature | 0-200℃( determined by seal material) |

| Cleaning D.P. | 50-100KPa(depending on the liquid viscosity) |

| D.P. Instrument | pressure transmitter/ differential pressure transmitter |

| Inlet&Outlet Standard | Flange, HG20592-2009(standard), HG20615-2009(ANSI B16.5 compatible);DIN11851 sanitary couling |

| Filter Element Series | MS/NS/AS |

| Housing Wet Part Material | 304/316L/CS |

| Piston Material | 316L |

| Scraper Material | PTFE |

| Housing Seal Material | NBR/EPDM/VITON/Silastic/FEP encapsulated Silastic |

| Element Seal Material | NBR/EPDM/VITON/Silastic/FEP encapsulated Silastic |

| Piston Rod Seal Material | NBR/PU/VITON |

| Purging Valve | Full-port pneumatic ball valve, single action or double action, material 304/316 |

| Facility Supply Requirement | 220V AC for control system, 0.4-0.6mPa clean and dry compressed air |

| Custom-made Design | Jacket design, Ex-proof design, Food grade design |

Filters on Jobsites

Applicable Liquid Types: wax, coal oil, monomer, polymer, citric acid, fermented broth, cosmetics, silicon solution, soap, sorbitol, steriodsugar, wet end additives, adhesives, inks, lubricating oils, coatings, resin, rubber, ethanol, miscella, edible oil, juice, diesel, etc.

|

1. Polymer Emulsion Filtration |

2. Latex Filtration |

|---|

| 3.Waste Oil Recycling Filtration | 4. Fermatation Broth Filtration |

|---|

Additional Information

MS Series Filter Element

Long slot screen. Interal slot width defined as the filtration degree. Wider outer slot width. The slot section shape is isosceles trapezoid. Rarely clogged, steady flowrate,high opening rate, uniform slots, filtration degree 50~1500µm. Smooth and flat internal surface is good roundness for being easily scraped clean. The 316L screen material is solid and durable with excellent chemical resistance. Good at filtering difficult impurities such as oil mud, soft particles, ect..

AS Series Filter Element

Manufactuered by the advanced micro-fabrication technology. It´s the pore screen and the internal pore diameter defined as the filtration degree. The outer pore diameter is larger. The pore channel is horn-shape. Rarely clogged, filtration degree 50~500µm. Round pore for absolute accurate filtration, 100% remove the particles larger than the filtration degree. For extremely high filtration quality application. Good at filtering difficult impurities such as oil mud, soft particles, fiber and ect..